In today’s complex supply chains, simply knowing the location of goods is only the first step. To truly guarantee product quality and safety, it’s necessary to have full traceability and understand the environmental conditions that products have been exposed to throughout their journey.

While a standard track and trace solution provides essential information like production methods, materials used, and certifications, the ability to add environmental data like temperature and humidity offers a significant evolution. This sensor data plays a critical role in maintaining the integrity of many products, from perishable foods and pharmaceuticals to other sensitive materials.

an enhanced approach which ensures customer satisfaction by proving the origin and careful management of your goods. By controlling the quality and sharing this data, customers can trust in the time, effort, and technology you’ve invested. Providing customers with this deeper geographical and environmental context is a real added value and a significant commercial advantage.

Maintaining product integrity requires accurate temperature and humidity monitoring. However, traditional methods like manual checks are inconvenient and prone to error, while battery-powered IoT solutions can be costly due to battery replacements and additional hardware. Battery-less sensory RFID offers a compelling alternative, enabling precise, real-time, and cost-effective environmental tracking. Leveraging your existing UHF RFID infrastructure for supply chain management allows you to integrate this sensor data into your warehouse management system and supply chain software, with no additional cost to access data.

This technology enables Track Sense Trace, the next evolution of tracking and traceability, building upon the established benefits of RFID in logistics and supply chain monitoring. This new approach empowers you to develop your business by reducing waste, optimizing processes, and enhancing operational efficiency and productivity.

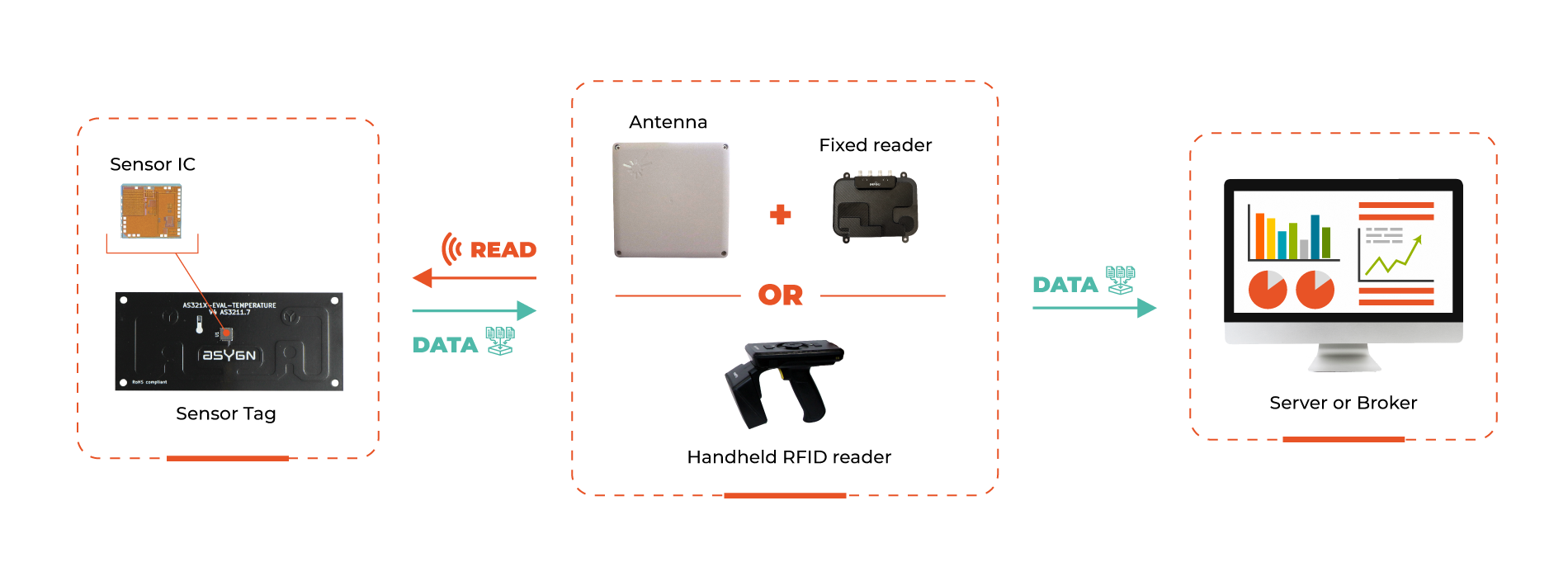

Items to monitor are tagged with RFID labels which provide real-time temperature, humidity and unique identification for each item.

Tags are read by RFID Readers and antennas installed at critical checkpoints, such as loading docks, warehouses, and receiving areas.

Finally, a centralized data management system, either cloud-based or

on-premise, provides a secure repository for storing environmental data.

Ensure traceability and compliance, guarantee freshness, and reduce waste with proactive cold chain temperature monitoring.

Safeguard drug safety and ensure proper distribution by tracing and monitoring conditions in primary packaging, prefilled syringes, or batches throughout the entire supply chain.

Prevent degradation and mold formation during transportation and storage of sensitive materials like wood and paper keeping trace of temperature and humidity.

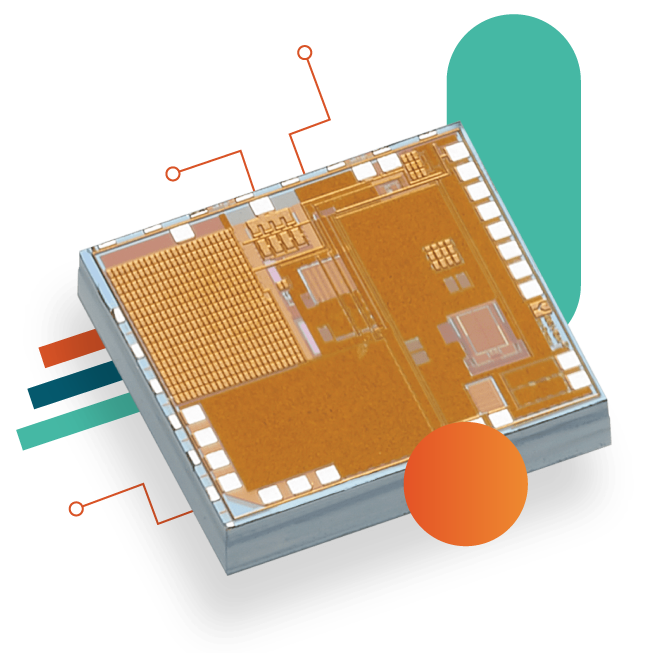

The AS321X chip family from Asygn is a game-changer in this field. This battery-free, EPC Gen2 compliant RFID chip is designed specifically for sensing applications, with a key focus on temperature, relative humidity, light or deformation.

Up to 7 meters reading range

including sensor supply

Internal / External Sensors

Temperature, Relative Humidity,

Ambient Light, Strain…

Battery free

Since the AS231x family is ISO and GS1 compliant, RFID sensory chips behave just like standard RFID. Any reader or existing infrastructure can be used to retrieve identification and sensory data.

Integration with EPCIS compatible software or ERP systems is straightforward. This allows you to comply to regulations such as FSMA 204 or Digital Product Passport (DPP) with no efforts.

Take a look at our web demo dashboard: some tags are deployed and read by a standard RFID reader. Results are sent to the cloud and available live 24/7.

The AS321X chip family exists in multiple versions: all feature temperature tracking by default, then relative humidity, strain and light can be chosen as additional embedded sensor.

Want to connect your sensor? Capacitive or resistive, this is possible: accelerometer, pressure, moisture or pick-to-light, it is up to you.